French Polishing is the technique of applying a 'varnish' (made up by dissolving Shellac flakes in alcohol), to a wooden surface by rubbing it on with a soft pad, rather than a brush, and then polishing the surface to a high gloss. Craftsmen discovered that a finer surface could be achieved if the varnish was applied with a soft pad rather than a brush because brushes always leave small ridges and the only way to obtain a truly smooth surface is to sand the brushed surface level with very fine abrasive papers. Although this method can achieve a good flat surface, it looks different to a French polished surface that has been finished 'straight off the rubber'. A French polished surface gives the appearance of being integrated into the wood, as if it grows organically from within. It is often described as being like gazing into a clear river, where the stones and sand on the bottom of the river look crystal clear and the depth is obvious.

The technique became popular late in the 18th century and much fine furniture was finished in this way. In earlier times, the mainly oak furniture was finished with oils and waxes. Then the Victorians adopted French polishing as the standard surface finish for fine furniture, much mahogany being finished this way.. Although the process takes time to do well, by not using a brush, the problem of having to use abrasive paper to rub down the ridges left by the brush does not arise. But in the 1940s mass producers of furniture found that the developing equipment that allowed spraying of various lacquers was quicker and produced more heat-resistant and durable surfaces. But for fine furniture and musical instruments, the beauty of a French polished surface cannot be bettered, and this is still the preferred method.

French polishing consists of rubbing on numerous coats of shellac until the surface has sufficient body to be polished smooth or burnished to a high gloss finish. This is the aim of a skilled polisher, although various stages of reduced or lesser gloss are achievable during the process. Much antique furniture looks at its best with a deep patina that allows the beauty of the wood to show through to its optimum. For this effect, a skilled polisher can initially use coats of shellac to produce a sound surface, which can then be cut back slightly with a traditional wax finish. This gives a far better and more original looking patina than simply apply wax direct to a raw timber surface. So many lesser stages where the process can be ended sooner to obtain different effects, depending on the item being polished, is a good approach to consider.

The French Polishing process takes time because very many applications are made, with several hours drying time between. It would be wrong to stipulate one method only, as polishers usually try out all sorts of ways of applying the shellac until they find the one that suits them best. Most important is to get the degree of wetness of the rubber or pad just right; - too wet, and a messy surface results, with ridges and marks that have to be sanded out before the next coat is applied. Too dry, and nothing much is applied to the surface and the finish remains too thin. The use of oil as a lubricant is also important to get right. Too much or not enough, and the result is unsatisfactory. The dilution of the shellac mixture is also critical; adding small amounts of extra solvent (industrial alcohol) as the polishing progresses ensures that the polishing pad works smoothly over teh surface without damaging the already applied shellac beneath. French polishing is a slow process that gradually builds up to provide the most attractive surface possible on wooden items.

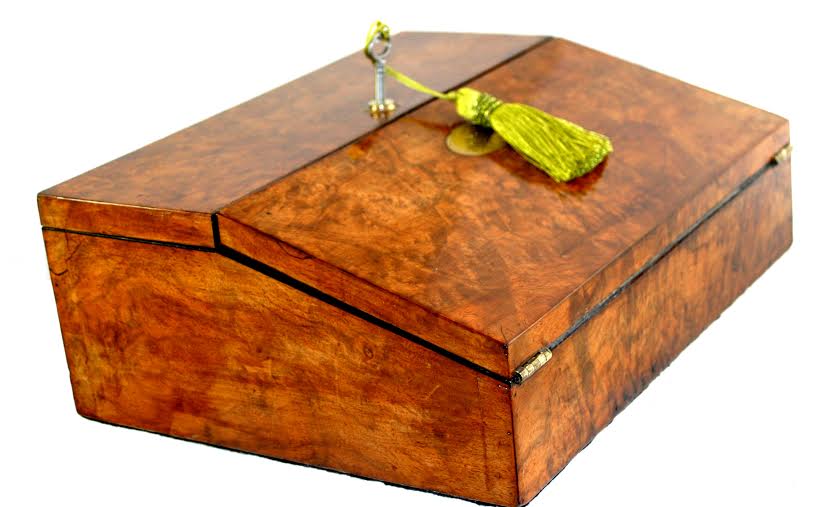

Burr walnut writing box restored and polished by Dawn